Electronic Work Instructions

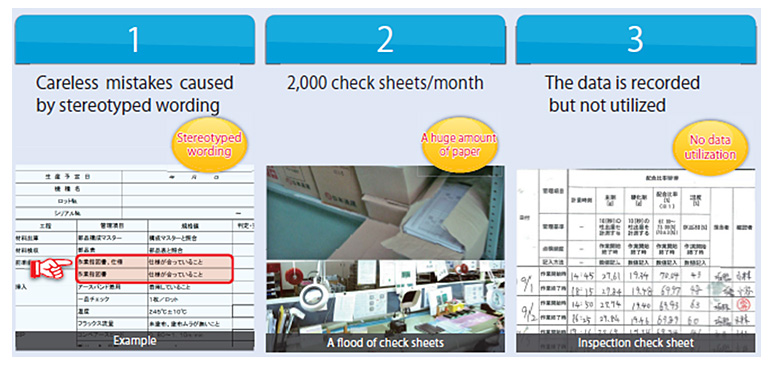

Issue : Hard to understand!

* Hard-to-understand paper instructions cause careless mistakes and higher failure costs.

* Time-consuming preparation causes “Muda (unproductiveness)”.

* Equipment status control is difficult.

* Uncertainty in on-site quality judgement causes higher quality assurance costs.

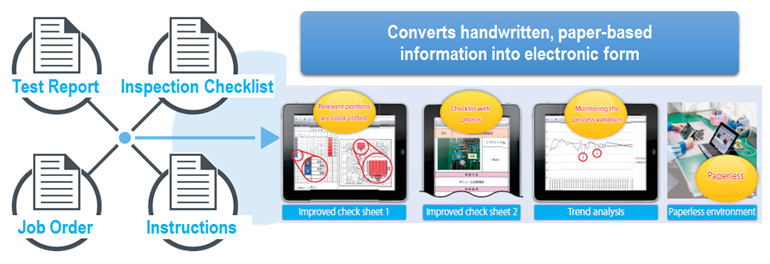

Solutions :

* Provides the electronic work procedures in order of process flow to prevent careless mistakes and level the production.

* Eliminates 3,000 sheets of paper/month used for work preparation.

* Makes a graph using the collected operational status data.

* Electrically publishes the quality standards that help the workers judge the conformance.

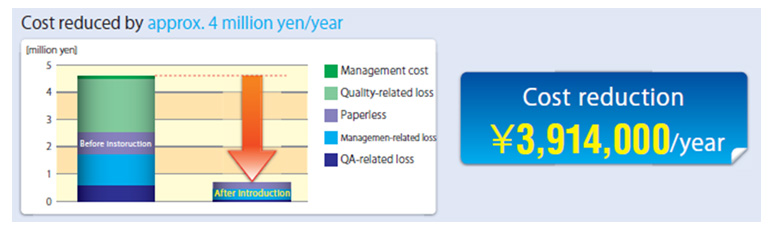

Benefits :

* The failure cost resulting from careless mistakes has been reduced to zero.

* The preparation-related print cost of 600,000 yen/year has been reduced to zero.

* The equipment status control has minimized unexpected problems.

* Sharing the quality standards and use of the video manuals have improved the worker productivity.

![Technotree [en]](https://en.technotree.com/wp-content/uploads/2017/06/cropped-logo_tecnotree.png)